Highly Frictional • Non-Leaching • Rot-Resistant • Non-Flammable • Durable • Safe

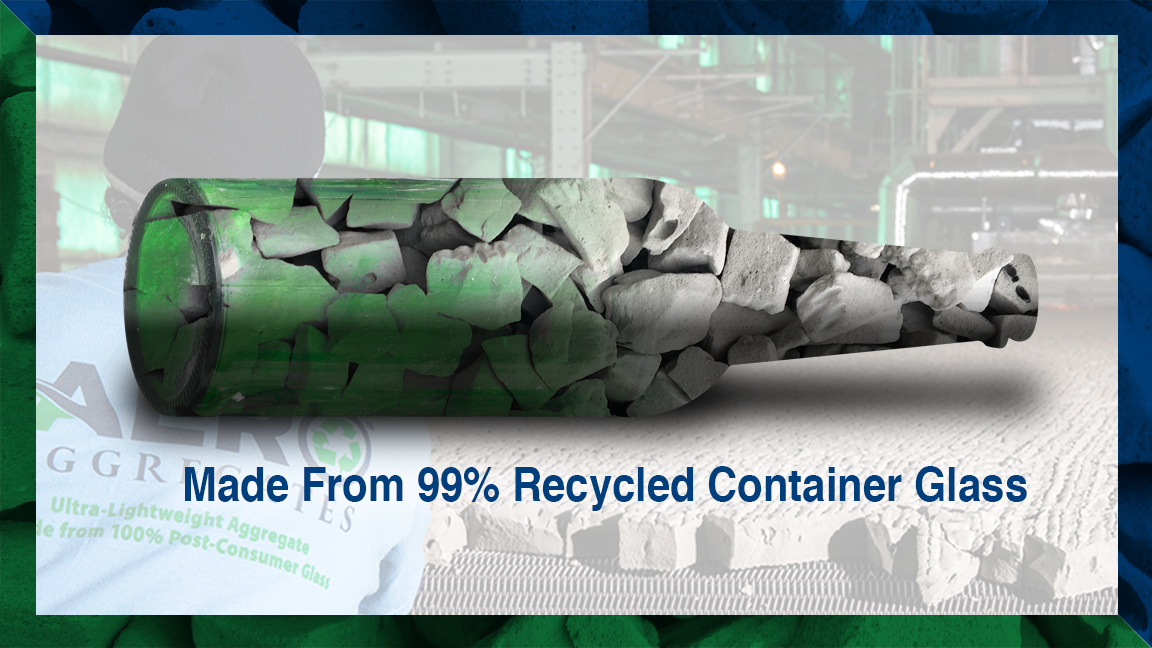

Aero Aggregates® Ultra-Lightweight Foamed Glass Aggregates (UL-FGA®) are made in North America from 99% recycled container glass. UL-FGA is one of the lightest aggregates on the market — 85% lighter than traditional aggregate and delivering up to 100 cu yds per truckload.

Each AeroAggregates location diverts the equivalent of over 140 million glass bottles per year from landfills and reduces the number of trucks on the road due to the increased volume per delivery!

AeroAggregates®

Ultra-Lightweight Insulation Fill For Infrastructure

A highly frictional closed-cell surface combined with a low unit weight, inertness, high permeability, and insulating properties, makes UL-FGA ideal as an ultra-lightweight backfill. Made from 99% recycled container glass.

Growstone®

Soil Aerator

Moisture Retention

An open-cell, lightweight, foamed glass aggregate ideal for use in most planting mixes. Made from 99% recycled glass. Growstone® provides oxygen and water at the root zone.

AeroLite®

Closed Cell Granulated Foamed Glass Aggregate

A closed-cell foamed glass offered in six gradations G1-G6.

If you think that Aero may be able to able to help one of our local or nearby communities through glass recovery and diversion or community outreach events or programs, please get in touch.